Ail_HeatOven_2

Heat Oven - 1

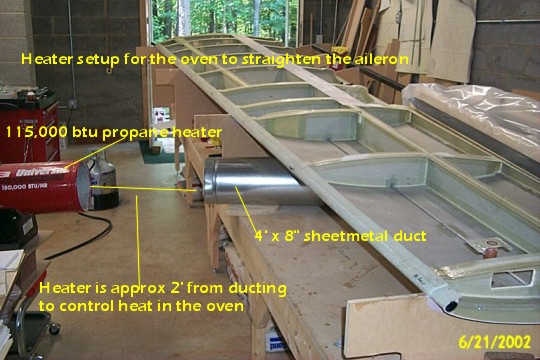

Note: In a lapse of sanity, we decided to close out the right alieron on the bench!! When it was cured, there was great consternation and weeping in the shop when we found that the TE was about 5/16" higher at the tip than at the inboard end. We had taken out the washout of the aileron!! Mark Mahnke at Lancair suggested building an "oven" and heating the aileron - attached to the wing and clamped to the TE support. The TE support was adjusted to a lower height equal to the distance of the warp in the aileron at the wingtip. We cranked up the propane-fired heater and let the temp in the interior of the aileron get to 160 degrees for 15 minutes. It was measured on a quick acting thermometer inserted in the end of the vent hole in the outboard aileron. The temp in the "oven" was held to 180 degrees for the whole process. After letting it cool gradually, the warp was gone and the aileron was lying perfectly flat on the steel TE support. It was flatter than the left aileron - the first one we did.

Note: In a lapse of sanity, we decided to close out the right alieron on the bench!! When it was cured, there was great consternation and weeping in the shop when we found that the TE was about 5/16" higher at the tip than at the inboard end. We had taken out the washout of the aileron!! Mark Mahnke at Lancair suggested building an "oven" and heating the aileron - attached to the wing and clamped to the TE support. The TE support was adjusted to a lower height equal to the distance of the warp in the aileron at the wingtip. We cranked up the propane-fired heater and let the temp in the interior of the aileron get to 160 degrees for 15 minutes. It was measured on a quick acting thermometer inserted in the end of the vent hole in the outboard aileron. The temp in the "oven" was held to 180 degrees for the whole process. After letting it cool gradually, the warp was gone and the aileron was lying perfectly flat on the steel TE support. It was flatter than the left aileron - the first one we did.