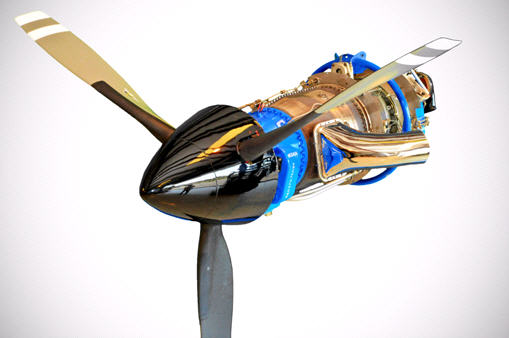

Diemech

Turbines

![]()

![]()

![]()

Repairs, Parts, Maintenance and Sales

|

Diemech

Turbines

|

|

|

|

|

|

|

|||||||

|

Company |

We perform overhauls (IRAN) of B, D,

or E engines in our facility with trained and experienced staff. Our

staff follows detailed factory standards, tolerances to

complete your overhauls. We pride ourselves in our quality and

continue to educate

our employees, continue upgrade test equipment and develop new parts

when replacements are not feasible.

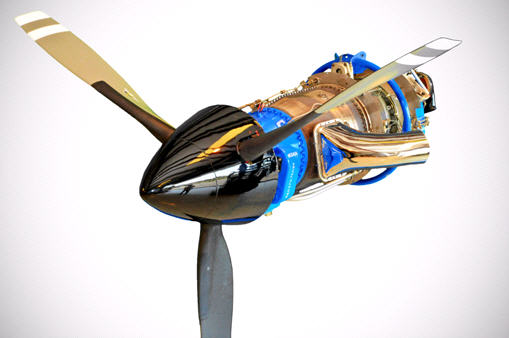

Engines that have been taken

care of, operated conservatively and with low cycle count relative to

total engine hours, typically leave here with few additional

charges. Engines that have been abused, suffered prop strikes, or

have been routinely operated at extreme limits tend to have more internal

issues and, accordingly, more components that need replacement.

Whenever possible we repair internal components rather than replace them,

simply because the repair process winds up being more economical than a

replacement part. If you wish to see more details for 'reasons

to overhaul' an engine, follow this link.

Once an engine is complete, it

is mounted on our newly refurbished test truck and ready for several hours

of testing which include factory recommended adjustments to maximize

engine performance. With each engine we ship out we provide you with

documentation that includes your engine performance, logbooks supported by

original factory documentation, parameter books, and various other power

reports. Your more than welcome to visit our shop to participate in

the engine run and training sessions.

GE-Walter and Diemech Turbines

acknowledge that Diemech turbines is a non FAA certified facility. |

|

|

|

Diemech

Turbines All

Rights Reserved

|